The lab furthermore specializes in all types of nitride systems and has previously studied thin film layers of GaN, ScN, CrN, FeN, MnN, Mn3N2, Mn4N, MnGaN, and CrGaN. Preparation of bi-layer systems such as Fe/CrN leads to being able to investigate complex magnetic properties arising from interfacial effects such as interfacial coupling.

Main research interests in the lab include:

1) quantum properties of complex materials and low-dimensional systems

2) electronic and magnetic properties in nitride systems

3) magnetic properties of transition metal and rare earth nitride systems

4) room-temperature ferromagnetism in 2-Dimensional MnGaN (MnGaN-2D)

5) spin Kondo (zero bias) resonances in ferromagnetic islands on magnetic nitride surfaces

Additional research interests:

6) Skyrmions in magnetic nitride systems

7) Novel quantum states such as Majorana zero modes in nitride materials

Phases of Research

Projects

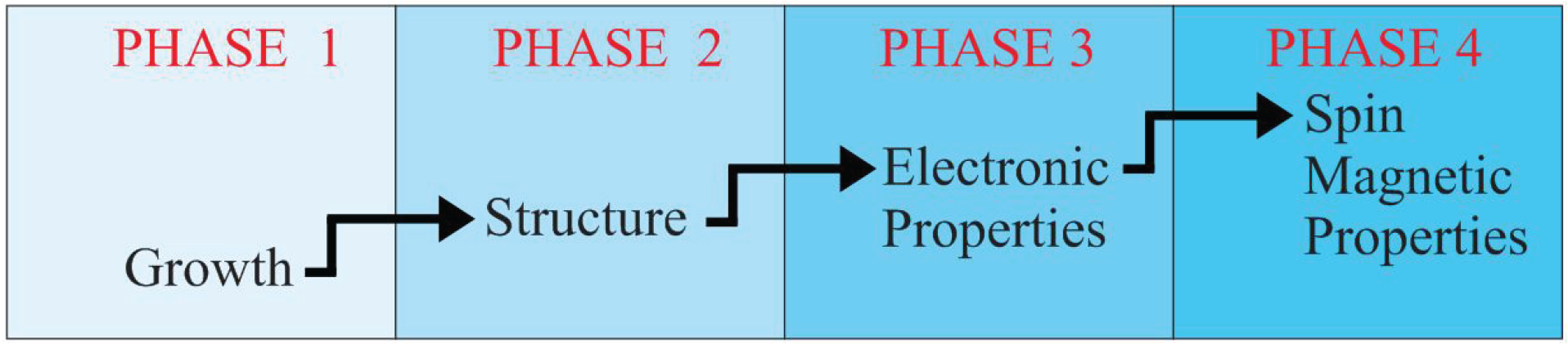

In the research performed in the group, there are often 4 stages to a successful project as shown in the following diagram. First we explore the growth of the material; second, we investigate the structural properties; once this is determined, it is possible to look into the electronic and spin magnetic properties. Magnetic properties can be closely related to the electronic properties as well.

In the research performed in the group, there are often 4 stages to a successful project as shown in the following diagram. First we explore the growth of the material; second, we investigate the structural properties; once this is determined, it is possible to look into the electronic and spin magnetic properties. Magnetic properties can be closely related to the electronic properties as well.